Club FOX!

#5101

You could also give the backplate area a whack with a piece of wood with the case hot as well - this has worked for me in the past as well. The fact is the aluminum case will expand more than the bearing when heated. Clearly there is crud around the bearing race and crankcase that is acting like glue. It will come out, it’s just gonna take more finesse and possibly using some out of the box methods. Where there’s a will there’s a way.

:

1. The first engine has ABC piston/sleeve, lower compression head button, EZJust carb, built-in spinner, and the Quiet Muffler.

2. The other two engines have the iron piston/steel sleeves, MkX carbs, and low nitro head buttons.

I will have to bench run them this Spring when weather permits.

#5103

Fox parts are hard to come by. If Mecoa doesn’t have them, try eBay or the forum classifieds. Put out a “wanted” ad. However, if all you’re looking for is o-rings and gaskets, I suggest making your own gaskets and get new o-rings from theoringstore.com.

#5104

There were quite a few Fox engines at our swap last night. Very reasonably priced too. PM a want list if you like. I can check with the locals,

#5105

Make a list of what you need and carry it to your next swap meet. I picked up a Fox .46 w/ the air bleed carb for cheap and passed on a .40 at $30 (I think it was that much). I have seen many Fox engine parts for sale still in the original packaging. Like what was said above, I wouldn't try to find gaskets (make them) and bearings are very easy to find.

carl

carl

#5106

I tested 2 of my C-case 40's (lapped iron piston/steel sleeve) this past weekend after replacing the bearings. One engine put out 13500 rpm but the second engine maxed out at 12300 rpm's only. The only thing I can attribute the difference to is piston wear. Both engines have the same exact cylinder measurements but the slower piston is 0.03 mm smaller due to wear. Although I expect loss of compression due to wear, does 0.03 mm make that much difference in performance?

I guess it would be nice to get a new piston and circlips for it. I found circlips at the MECOA site for this engine, but not pistons.

I guess it would be nice to get a new piston and circlips for it. I found circlips at the MECOA site for this engine, but not pistons.

Last edited by hsukaria; 04-15-2019 at 10:36 AM.

#5107

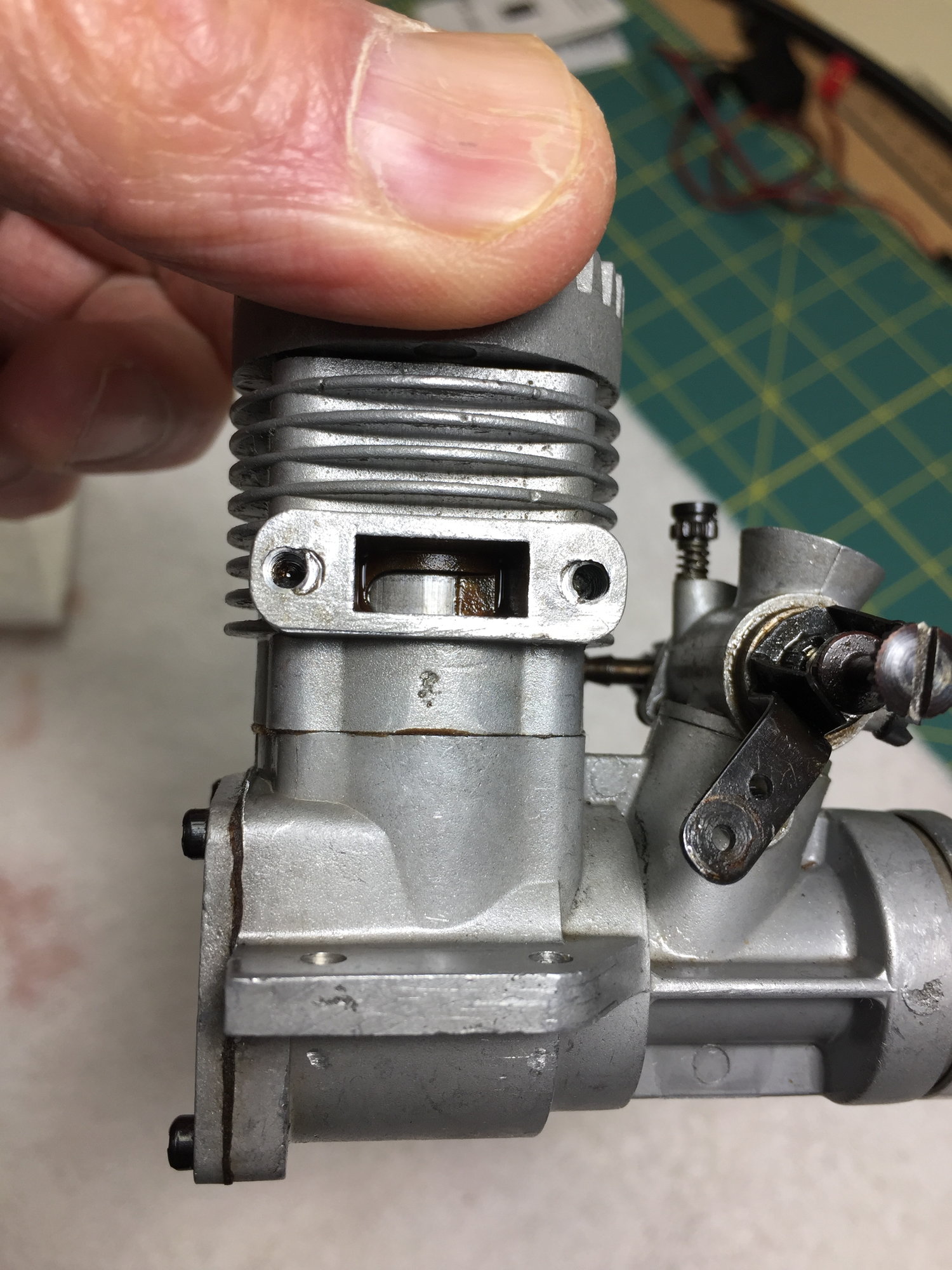

I recently acquired my first Fox engine , a 25 BB R/C, at a swap meet .The engine has no markings to indicate that it is a Fox, nor any stamping on the mounting lugs to indicate capacity. It has the tilt-up muffler and MK-X carb. I ran the engine on the bench with an APC 10X4 on Cool Power 15%. Full throttle gave me 7900 rpm and 5400 rpm on idle. The figures recorded seemed way off. I have attached some images of the engine and the exhaust port. Other than the larger prop and synthetic fuel ,which was what I had on hand, any suggestions on what was causing the skewed results?

Compression is strong, plug is an OS #8, HS needle was adjusted for max rpm , LS needle was adjusted for smooth transition and lowest steady rpm. Engine run was messy with fuel/oil spitting from the muffler and front bearing areas. Surprisingly, the engine running without muffler seemed quieter than some of the diesels I run. I took a picture of the exhaust port as I am intrigued by the size of the exhaust opening in the liner. It seems too small and restricted and wondering if the position of the liner is incorrect. In my Google search, I have not come across a picture of the exhaust port for the Fox 25 BB so am not sure what it should look like.

Any help would be most appreciated.

Compression is strong, plug is an OS #8, HS needle was adjusted for max rpm , LS needle was adjusted for smooth transition and lowest steady rpm. Engine run was messy with fuel/oil spitting from the muffler and front bearing areas. Surprisingly, the engine running without muffler seemed quieter than some of the diesels I run. I took a picture of the exhaust port as I am intrigued by the size of the exhaust opening in the liner. It seems too small and restricted and wondering if the position of the liner is incorrect. In my Google search, I have not come across a picture of the exhaust port for the Fox 25 BB so am not sure what it should look like.

Any help would be most appreciated.

#5109

My Feedback: (156)

Does anyone know how to tell the Fox Quickie .40 Special from the Quickie Sport?

I know the Special has the larger carburetor and radical timing, but assuming neither engine has a long tuned or standard muffler bolted on, HOW can a person tell them apart by appearance??

Both engines have the letter 'Q' stamped on the side.

I know the Special has the larger carburetor and radical timing, but assuming neither engine has a long tuned or standard muffler bolted on, HOW can a person tell them apart by appearance??

Both engines have the letter 'Q' stamped on the side.

#5110

I decided to take off the button head and check the exhaust port. It was not in the right position. The transfer port opening position was switched with the exhaust opening. Running the engine after reassembling, I recorded an idle of around 3050 rpm and a high of around 12650 rpm. I used the same fuel as before, Cool Power 15%, but changed the prop to a Graupner 9 X 5. I also added an O-ring under the carb, and a muffler gasket and it reduced the oily messiness, although, I suspect it is still leaking oil from the front bearing area. Best of all, the Fox "bark" is now noticeable! I still have to figure out how to eliminate the HS needle "wobble" as it affects the rpm on the high side. I tried a short length of fuel tubing to stabilize the needle and rpm but it doesn't seem to be helping. Any suggestions are most welcome. On a side note, has anyone used a different brand of carb on the 25 BB? Thanks.

#5114

Thanks for you reply, Jim. I did rotate the liner to the correct position and it transformed the engine. The compression still feels very strong and am hoping any previous runs have not affected the piston/liner fit too drastically. I plan on adding some Klotz Benol to increase the oil content of the Cool Power 15%.

Any feedback on pros/cons of the tilt-up vs. the tilt-down muffler?

Any suggestions for a different brand of carb to fit this engine?

Thanks

Any feedback on pros/cons of the tilt-up vs. the tilt-down muffler?

Any suggestions for a different brand of carb to fit this engine?

Thanks

#5115

Thanks for you reply, Jim. I did rotate the liner to the correct position and it transformed the engine. The compression still feels very strong and am hoping any previous runs have not affected the piston/liner fit too drastically. I plan on adding some Klotz Benol to increase the oil content of the Cool Power 15%.

Any feedback on pros/cons of the tilt-up vs. the tilt-down muffler?

Any suggestions for a different brand of carb to fit this engine?

Thanks

Any feedback on pros/cons of the tilt-up vs. the tilt-down muffler?

Any suggestions for a different brand of carb to fit this engine?

Thanks

I recommend the next time you purchase fuel to get it with 20% castor. It is actually cheaper than the synthetic and that is what your engine was designed for.

I'm not sure about changing out the carb, all the Fox carbs I ever dealt with were excellent. Even the old butterfly versions. Admittedly, I only dealt with sizes .40 and up.

#5116

I need some advice on my Fox 45 beater engine. I noticed a little slop between the rod to crankpin. I measured about 0.01 inch of play. Is that a problem? Should I get a new rod, assuming one can be found? Thanks.

#5117

My Feedback: (2)

Join Date: Dec 2001

Location: Kerrville,

TX

Posts: 2,127

Likes: 0

Received 0 Likes

on

0 Posts

I think the tilt-up mufflers were meant for side or inverted mounting. Tilt-up mufflers might not be good if the engine is mounted upright because it causes accumulation of exhaust fluids in it.

I recommend the next time you purchase fuel to get it with 20% castor. It is actually cheaper than the synthetic and that is what your engine was designed for.

I'm not sure about changing out the carb, all the Fox carbs I ever dealt with were excellent. Even the old butterfly versions. Admittedly, I only dealt with sizes .40 and up.

I recommend the next time you purchase fuel to get it with 20% castor. It is actually cheaper than the synthetic and that is what your engine was designed for.

I'm not sure about changing out the carb, all the Fox carbs I ever dealt with were excellent. Even the old butterfly versions. Admittedly, I only dealt with sizes .40 and up.

CR

#5118

I have a new problem with my Fox 40 ABC. I decided to replace the crankcase because the aft muffler mounting hole broke (I wasn't using a Fox muffler). I purchased a new crankcase from MECOA and it arrived in perfect condition. However, the fit between the crankcase and crankshaft is super tight and there is enough binding that the crankshaft does not rotate unless I force it with a mounted propeller. I checked that the bearings are not the culprit and they aren't by sliding the shaft through the crankcase without the bearings installed. It seems that the crankcase opening is in need of enlarging.

Anybody know how to go about enlarging the case to prevent binding with the crankshaft? I must admit this is a new to me, never had to deal with this before.

Anybody know how to go about enlarging the case to prevent binding with the crankshaft? I must admit this is a new to me, never had to deal with this before.

Last edited by hsukaria; 10-27-2019 at 12:56 PM.

#5119

Before doing the following be certain that all the thin shims, and spacers , if there are any, are in their proper location on the shaft. Then see if the shaft will rotate without the prop mounted. Sometimes if these spacers are not properly located, the engine will bind up when you tighten the propeller. If it's still tight proceed with the following. Pop the bearings out, and look into the journal to see where it is dragging. If you can see that there is a tight spot, wrap 400 to 600 grit sandpaper around a dowel and sand the high spot. If that doesn't loosen it up, select a square piece of wood that is a loose fit in the journal, and wrap the same sandpaper around it until it is a snug fit. Turn it gently to remove a small amount of material. You might have to slit your stick, and slip the sandpaper in the slot, so that the sandpaper will turn with the stick. This sounds like a crud fix, but it's not. The tolerance between the shaft, and the case isn't that critical. A real sloppy fit will just let fuel weep out the front bearing. Your engine probably has a sealed front bearing which should keep excessive fuel from coming out the front of the engine. You could also return the case. Good luck, and let us know if you get it fixed.

#5120

gary meyers <[email protected]>

9:14 PM (0 minutes ago)Hi ! -- Fox used to have a product they called Lustrox (if spelling is right) and I still have some. The process is that you mixed a small amount in oil, anykind of oil will do for this, then lube the crankshaft, with the mixture. after several rotations the crank should move more smoothly. Using a starter to work in the lustrox mix is ok as long as you don't overdo. Lustrox is an extremely fine abrasive.

I'd mail you some if you let me know where to send it. Fox also recommend the use of lustrox to break in their old cast iron sleeves and steel pistons by mixing the oil/lustrox and driping it into the venturi while running. I used it last for a tight fitting conrod/crankpin and it worked great.

once satisfied with the smooth shaft you should probably flush the lustrox and relube the crank.

Gary

314 749 6734

#5121

Lustrox is a fine lapping compound. You could certainly give it a try. It might take a lot of spinning. I wouldn't recommend poring in the venuri of a running engine though. Too much collateral damage. Spinning up the crank with your starter sounds like a good idea, except that you will have to do it with the bearings in, so there is a chance you will get Lustrox in the bearings. It might not hurt them, but I wouldn't want to take the chance. If you had a set of disposable bearings you could install them for the Lustrox procedure, and then reinstall your good bearings.

#5122

I carved out the broken muffler mount to glue in a piece of aluminum and then drill and tap a new hole.

Greg, I do have a set of disposable bearings from the old crankcase with the broken muffler mount hole. Repairing the old crankcase will be my next task after this fix.

Gary, I will accept your generous offer for some Lustrox if still available. I will PM you with my mailing info.

Old crankcase opening is 0.50 inch. New crankcase opening is 0.4985 inch. Enough difference to cause the binding.

#5124

#5125

Senior Member

My Feedback: (3)

I would think anything with a fine abrasive such as a rubbing compound may work. I would mix it with a light oil before applying it to the crank and/or case bore.

I found my new go to rub this side of the border from Canadian Tire. It is a 3M marine polish that will clean anything. Wish I had take pics of the hobby trailer before and after. The rims especially had heavy rust staining. Only restriction to your app would be this also has a wax.