Welcome to Club SAITO !

My Feedback: (1)

that hole I drilled and tapped on my FA100 I did on my SherLine Mill, drilling and tapping small things is about all I used it for now

Jim

Last edited by the Wasp; 12-27-2019 at 07:42 PM.

Dave,

Great news on the lathe!!!!

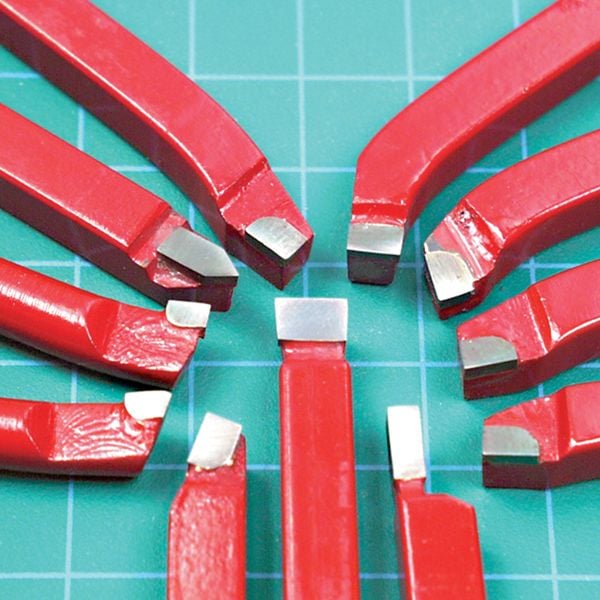

I am happy to see you taking the plunge. Get on YouTube and you will see how easy they are. Let your imagination mingle with common sense, plan the job and work holding setups before you start. I have a lot of spare cutters etc, Let me know what size your tool holder takes. I can send stuff along with the 120 kit , in a flat rate box.

Cool Cool Cool ! Looking forward to some trick stuff from the Dairy Farmer in Virginia.

Yahoooooo

Great news on the lathe!!!!

I am happy to see you taking the plunge. Get on YouTube and you will see how easy they are. Let your imagination mingle with common sense, plan the job and work holding setups before you start. I have a lot of spare cutters etc, Let me know what size your tool holder takes. I can send stuff along with the 120 kit , in a flat rate box.

Cool Cool Cool ! Looking forward to some trick stuff from the Dairy Farmer in Virginia.

Yahoooooo

Senior Member

Thanks all, I have a book coming by David Fenner that'll get me some knowledge along the lines of what I'll need. Gary, I know you'll pitch in with some thoughts when I mention something I want to accomplish. Thanks for the Yahoooooo, I thought you all might think me crazy doing this at 77 years old. I am looking forward to the 120 "stuff". Our daughter Susan is going to say, "that's more Bovine Feces I'll have to get rid of when you croak." But I'll croak happy.

I'll definitely check out You Tube

I'll definitely check out You Tube

Last edited by 1200SportsterRider; 12-28-2019 at 03:24 AM.

Senior Member

Surly you jest. I was agreeing with you. Verbiage is for lighthearted illustration when so offered.

The Mutants you speak of were my relatives. Citizens.

The products their intellect and hands produced were and are superior on the world stage. Won wars for me. Gave me freedom to go down the road on those ancient outmoded time machines. I am amazed and thankful for ugly motorcycles.....

Help Dave with the torque adapter eh.

I am too verbiage heavy for technical writing.

Still want a couple of them FG carbs now that they got mentioned again. Probably give a dead rats patoot or two for a couple!

LOL

The Mutants you speak of were my relatives. Citizens.

The products their intellect and hands produced were and are superior on the world stage. Won wars for me. Gave me freedom to go down the road on those ancient outmoded time machines. I am amazed and thankful for ugly motorcycles.....

Help Dave with the torque adapter eh.

I am too verbiage heavy for technical writing.

Still want a couple of them FG carbs now that they got mentioned again. Probably give a dead rats patoot or two for a couple!

LOL

Maybe, with my new lathe I can get a couple of new Tork-It bits and convert them to Ball Drivers.

Beats the way I make them Dave, with files. Some of my more common sizes of ball end hex wrenches have been cut off and reprofiled a half a dozen times in the 20+ years I've owned them. It takes me about 15 minutes of careful filing to get the ball profile just right. Not too bad but I do wish I had a lathe in the shop.

That Micro Mark Sieg C1 does look like a handy little guy to have around. I've been looking for a used lathe locally for the past couple of years, one with a lead screw, but haven't found the killer deal yet.

That Micro Mark Sieg C1 does look like a handy little guy to have around. I've been looking for a used lathe locally for the past couple of years, one with a lead screw, but haven't found the killer deal yet.

Senior Member

My first effort will be to make two adapters to fit Saito 30 mufflers to the 60 twin. I have the black 90's that are kind of crude looking but strong, so I'll need to go from female 10 x 0.1 to female 9 x .75.

Senior Member

Here you go, I got the last two MacGregor's had.

Apparently they didn't do the 9 mm until the little 30 and FA 40-a came along. I don't know for certain though.

SAI50163 - Muffler Right Angle Manifold M10

Apparently they didn't do the 9 mm until the little 30 and FA 40-a came along. I don't know for certain though.

Hey Dave, seeing as your new lathe doesn't have a lead screw for cutting threads check out this vid.

He has made a die holder, you can too, that spins freely once released by hand. Perfect for lathes without lead screws. He shows a couple of other tricks for cutting nice straight threads when using a standard die handle too.

He has made a die holder, you can too, that spins freely once released by hand. Perfect for lathes without lead screws. He shows a couple of other tricks for cutting nice straight threads when using a standard die handle too.

Senior Member

Thanks, I'll check that out.

Saito has modified the cam support shaft to allow easier lube flow, the relief lines up with the lube hole in the cam. It even has a tiny O-ring on the forward end.

Saito has modified the cam support shaft to allow easier lube flow, the relief lines up with the lube hole in the cam. It even has a tiny O-ring on the forward end.

Last edited by 1200SportsterRider; 12-28-2019 at 07:45 AM. Reason: Add picture

I made something like that for Dave a few years ago. Dave when drilling, tapping or threading aluminum use one of the specialty premium fluids. Tap Magic or A-9 are excellent choices. Can get you any tap , drill or die you need, especially metric. Just drop a line.

Senior Member

Thanks much, I have 10 x 1 die, a 10 x 1 tap and a 9 x .75 tap, I think I'm good to go for now. Thanks again.

These are the 10 x .1 elbows where I'll start.

A Joe Bridi RCM 60 where the 60 twin will ride. The tri stock is not behind the firewall yet, so it will be easy to adapt.

These are the 10 x .1 elbows where I'll start.

A Joe Bridi RCM 60 where the 60 twin will ride. The tri stock is not behind the firewall yet, so it will be easy to adapt.

Last edited by 1200SportsterRider; 12-29-2019 at 08:10 AM.

One day I need to order a new power supply for my Sherline CNC controller and give it another try. I just haven't set time aside to draw up plans yet for anything to actually make on either the mill or lathe, but have used the lathe a couple times for small parts. I just need some scrap stock to play with, and may head over to Rockford and do some bin digging when I have time off.

"Draw Plans" ??? Wow, you are indeed organized.

I am lucky when I have a half dozen dimensions on an old sheet of cardboard.

Especially with CNC where the machine draws it for you.!!!

Good on you!

I am lucky when I have a half dozen dimensions on an old sheet of cardboard.

Especially with CNC where the machine draws it for you.!!!

Good on you!

Landing gear for the P-61, need to draw them out so they fit the plane, then can transfer to the computer, problem is, never used the software for the Sherline. I am still struggling for the laser with Coreldraw and Lightburn, though starting to get the hang of it more each time. Both have limits that I wish were easier to use, such as erasing or what used to be called Trimming in older versions I used, and Lightburn doesn't even have a means to trim nor to get dimensions. Since the Sherline software runs on a dedicated Linux machine and is hardwired to the controller, it can only be accessed via the console at the machine, so haven't even set it up yet until I get the power supply for it.

Been too busy with the Liberty Sport and getting the parts in the computer for that one, but getting close to finishing it and can then refine the parts that need it and start cutting a few sample kits the the two Mikes here.

Been too busy with the Liberty Sport and getting the parts in the computer for that one, but getting close to finishing it and can then refine the parts that need it and start cutting a few sample kits the the two Mikes here.

Oh yes, it has to fit

I fully understand that concept. Make loads of landing gear here. I usually just write down the key dimensions like base size, hole patterns, spread , trail, height etc. Do the math and layout directly on the metal. Trim, brake deburr and mount.

The company hardly ever gives drawings any more, just math data for machined parts.

I LOVE getting a drawing when somebody orders a part but seldom generate them for my own work, especially when CNC machining on something like a Prototrac machine. With them you dump in the numbers and it does the stuff you used to do with pencil and paper.!!!

LOL, amazing how computers have dumbed down the metal working, one time "skilled trades".

I still enjoy setting up rotary tables, angle plates and sine bars. Tooling balls and Jo blocks. But at home now. They do it differently at work.

Its all good though

I fully understand that concept. Make loads of landing gear here. I usually just write down the key dimensions like base size, hole patterns, spread , trail, height etc. Do the math and layout directly on the metal. Trim, brake deburr and mount.

The company hardly ever gives drawings any more, just math data for machined parts.

I LOVE getting a drawing when somebody orders a part but seldom generate them for my own work, especially when CNC machining on something like a Prototrac machine. With them you dump in the numbers and it does the stuff you used to do with pencil and paper.!!!

LOL, amazing how computers have dumbed down the metal working, one time "skilled trades".

I still enjoy setting up rotary tables, angle plates and sine bars. Tooling balls and Jo blocks. But at home now. They do it differently at work.

Its all good though

My Feedback: (1)

oh boy guys so tell me if this is going to be a problem for me in the air ??

so a while back I called SIGS and asked if the 4-Star 64 ARF tail feathers will fit my 4-Star 60 ARF and I was told yes, so I ordered them. when I received them I looked at them and put them aside, well, now that I am ready to glue them on to the fuselage I find that the 64 horizontal stab's span is 2& 1/2" shorter than the 60's stab,, I don't wish to loose stability, so considering I will be using a heavy engine is this going to be a problem in the air ??

just a side note here,

my plan is to use my Saito 100 Twin, so to have more lift for the extra wight I decided not to shorten the wing, I will only round the tips to give the plane an older vintage look.

oops, an edit> when I called, SIGS didn't have any 4-Star 60 ARF tail feathers, that is why I asked about the 64 parts.

thanks !!

Jim

so a while back I called SIGS and asked if the 4-Star 64 ARF tail feathers will fit my 4-Star 60 ARF and I was told yes, so I ordered them. when I received them I looked at them and put them aside, well, now that I am ready to glue them on to the fuselage I find that the 64 horizontal stab's span is 2& 1/2" shorter than the 60's stab,, I don't wish to loose stability, so considering I will be using a heavy engine is this going to be a problem in the air ??

just a side note here,

my plan is to use my Saito 100 Twin, so to have more lift for the extra wight I decided not to shorten the wing, I will only round the tips to give the plane an older vintage look.

oops, an edit> when I called, SIGS didn't have any 4-Star 60 ARF tail feathers, that is why I asked about the 64 parts.

thanks !!

Jim

Last edited by the Wasp; 12-29-2019 at 07:45 PM.

Jim, the horizontal tail surface area should equal approx 15%-20% of the wing surface area. If it's a little less than 15% that's ok, you'll probably just have to correct with more trim to maintain level flight. The Sig 4* design is a very stable one, it's meant to aid the beginner/intermediate pilot in adapting to low wing tail dragger flying. I think it'll fly fine with the smaller horz stab however the aircraft will be more sensitive to wind gusts as well as changes in cg location.

Installing the heavier engine will require shifting or adding weight of course, but it will also damp the responsiveness of the aircraft a bit. Just make sure you maiden with the cg at the more forward specified location and deliberately land at slightly higher speeds do the heavier wing loading. After that you can begin moving the cg rearward a little at a time until you're happy with the flight characteristics.

Installing the heavier engine will require shifting or adding weight of course, but it will also damp the responsiveness of the aircraft a bit. Just make sure you maiden with the cg at the more forward specified location and deliberately land at slightly higher speeds do the heavier wing loading. After that you can begin moving the cg rearward a little at a time until you're happy with the flight characteristics.

Last edited by Glowgeek; 12-30-2019 at 05:16 AM.

Junior Member

Join Date: Dec 2019

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts