Welcome to Club SAITO !

Saito used a special reducing bushing on radials in order to adapt the smaller exhaust port up to a larger pipe.

I do believe that I ssnt some to Dave a couple years ago.

I do believe that I ssnt some to Dave a couple years ago.

Last edited by Jesse Open; 05-04-2023 at 07:00 PM.

My Feedback: (1)

well I have had enough for today. I guess it's time to go to bed. can some tell me where I can find/buy a 5/16x20 left hand tap ???

the guy will give me my money back. he found my Lead Screw is most likely 5/16x20, my Lead Screw OD is correct (.312" ) and it is 20 tooth per-inch. my Jett lathe is older than the Grizzly so he doesn't make the standard thread nut. but I have asked him if I buy the tap will he make a nut for me. hopefully he will.

Jim

the guy will give me my money back. he found my Lead Screw is most likely 5/16x20, my Lead Screw OD is correct (.312" ) and it is 20 tooth per-inch. my Jett lathe is older than the Grizzly so he doesn't make the standard thread nut. but I have asked him if I buy the tap will he make a nut for me. hopefully he will.

Jim

Last edited by the Wasp; 05-05-2023 at 12:03 AM.

Senior Member

My Feedback: (3)

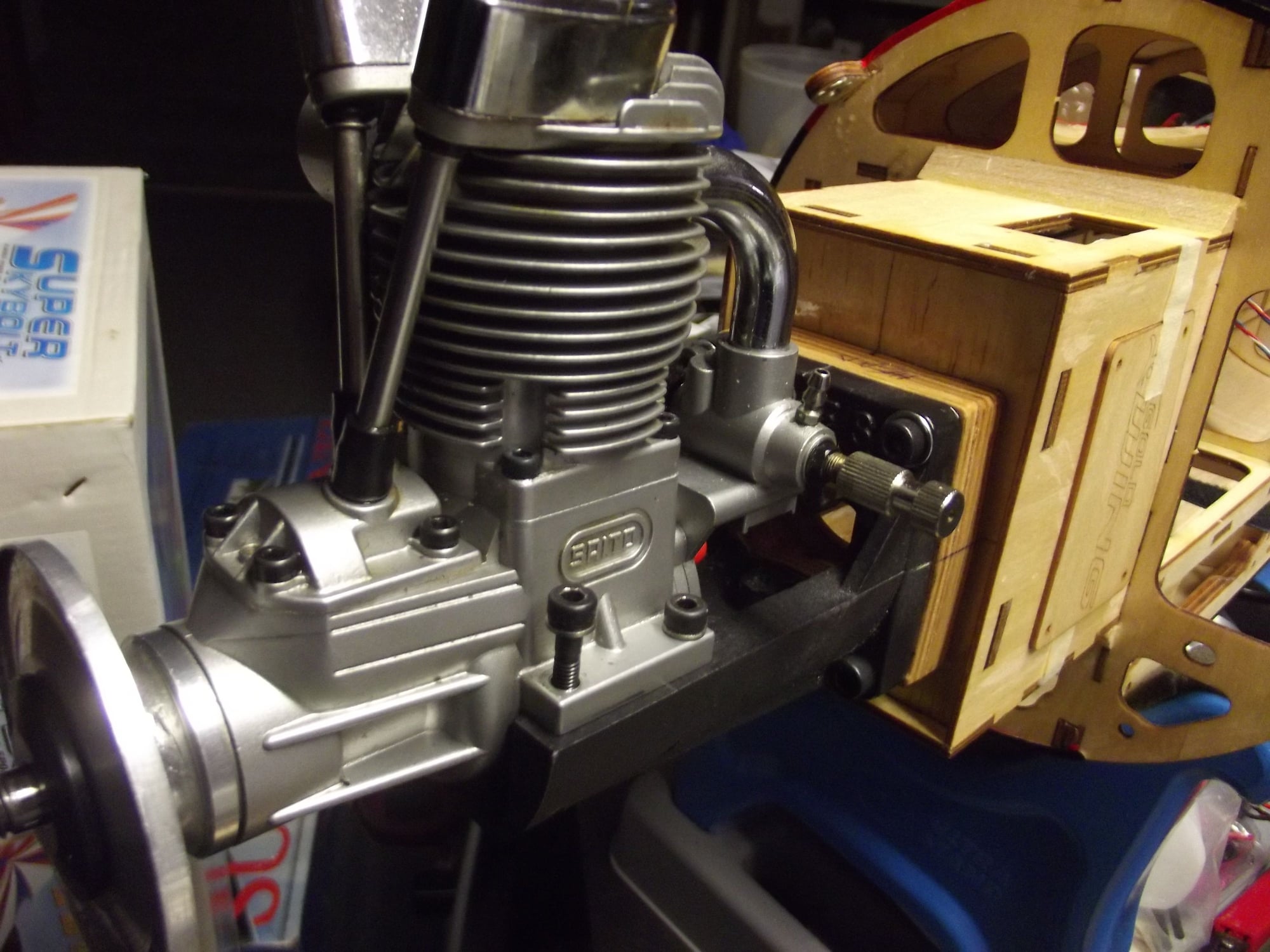

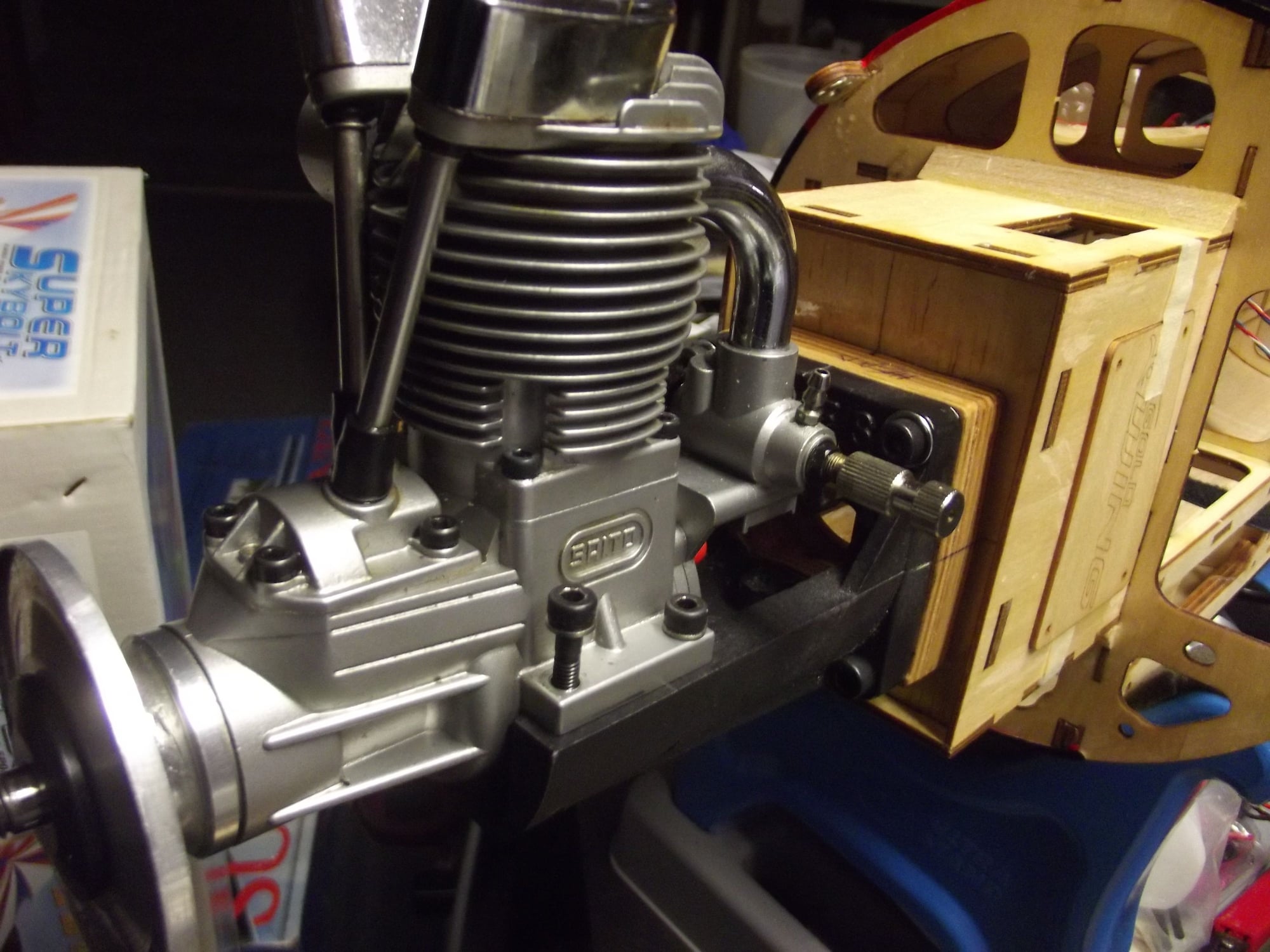

O/K, have a question for everyone here. Years ago I rebuilt a 150 and after testing sold it to a friend I taught to fly. May have the chance to get it back.

Reason is I am getting close on this years build project, a 30CC Goldwing Pitts Python. Have been fastidiously keeping the weight down, but with the heavier servos final AUW may push 12-13 lbs. Know the 125 bolted on now would make it fly, but not likely hover. Wondered if the 150, at the rated 2.5 HP would have the pull.

NOTE: The recommended DLE 30 specs out for 3.7 HP. If went that way would need an entirely new support system, (storage, pump, etc) and would need to keep it stored in the trailer due to smell. Would prefer to remain nitro, even if invested in ignition system.

Thoughts on this one?

Reason is I am getting close on this years build project, a 30CC Goldwing Pitts Python. Have been fastidiously keeping the weight down, but with the heavier servos final AUW may push 12-13 lbs. Know the 125 bolted on now would make it fly, but not likely hover. Wondered if the 150, at the rated 2.5 HP would have the pull.

NOTE: The recommended DLE 30 specs out for 3.7 HP. If went that way would need an entirely new support system, (storage, pump, etc) and would need to keep it stored in the trailer due to smell. Would prefer to remain nitro, even if invested in ignition system.

Thoughts on this one?

Last edited by Cougar429; 05-05-2023 at 02:09 AM.

O/K, have a question for everyone here. Years ago I rebuilt a 150 and after testing sold it to a friend I taught to fly. May have the chance to get it back.

Reason is I am getting close on this years build project, a 30CC Goldwing Pitts Python. Have been fastidiously keeping the weight down, but with the heavier servos final AUW may push 12-13 lbs. Know the 125 bolted on now would make it fly, but not likely hover. Wondered if the 150, at the rated 2.5 HP would have the pull.

NOTE: The recommended DLE 30 specs out for 3.7 HP. If went that way would need an entirely new support system, (storage, pump, etc) and would need to keep it stored in the trailer due to smell. Would prefer to remain nitro, even if invested in ignition system.

Thoughts on this one?

Reason is I am getting close on this years build project, a 30CC Goldwing Pitts Python. Have been fastidiously keeping the weight down, but with the heavier servos final AUW may push 12-13 lbs. Know the 125 bolted on now would make it fly, but not likely hover. Wondered if the 150, at the rated 2.5 HP would have the pull.

NOTE: The recommended DLE 30 specs out for 3.7 HP. If went that way would need an entirely new support system, (storage, pump, etc) and would need to keep it stored in the trailer due to smell. Would prefer to remain nitro, even if invested in ignition system.

Thoughts on this one?

My Feedback: (1)

well buys, you got to do what you got to do. I can't let me lathe set for years and years. or sell it broken for nothing. I sent my broken Slide Nut to the guy and his metric Lead Screw don't fit the nut. so my lead screw must be a standard thread, Left Hand 5/16x20 as I have always believed. so I ordered the Tap and correct drill "G". I hated to pay $67 for a tap I will use just once but I looked and looked and looked and could not find one that cost less. but I will have my lathe back. they should be hear Monday. I have a guy that wants me to make him some brass hose barbs for his old out board engine.

PS. where is everyone.

Jim

PS. where is everyone.

Jim

My Feedback: (6)

well buys, you got to do what you got to do. I can't let me lathe set for years and years. or sell it broken for nothing. I sent my broken Slide Nut to the guy and his metric Lead Screw don't fit the nut. so my lead screw must be a standard thread, Left Hand 5/16x20 as I have always believed. so I ordered the Tap and correct drill "G". I hated to pay $67 for a tap I will use just once but I looked and looked and looked and could not find one that cost less. but I will have my lathe back. they should be hear Monday. I have a guy that wants me to make him some brass hose barbs for his old out board engine.

PS. where is everyone.

Jim

PS. where is everyone.

Jim

Are your feed dials marked in metric or inch units? They put inch threads on inch lathes and metric threads on metric calibrated lathes.

How far do the dials show per revolution?

Bear in mind, many dials read double the actual movement because they are reading the overall diameter, not the radius from center.

My Feedback: (1)

my dials are standard. and they are very acute, so their diameter is correct to the thread's (20) tooth count. I will have to test it again when I get my new nut. god I hope it's the correct tap.

someone tell me how the Acme thread is different? cause my tooth gauge fits the tread perfect.

Jim

someone tell me how the Acme thread is different? cause my tooth gauge fits the tread perfect.

Jim

My Feedback: (1)

OK, I looked up the Acme thread on the net, my Lead screw threads have a sharper angle, and the crest is sharp, unlike Acme's.

I got to say I have seen them many times over the years. but as for the name, it's been a long time since machine shop in high school.

Jim

I got to say I have seen them many times over the years. but as for the name, it's been a long time since machine shop in high school.

Jim

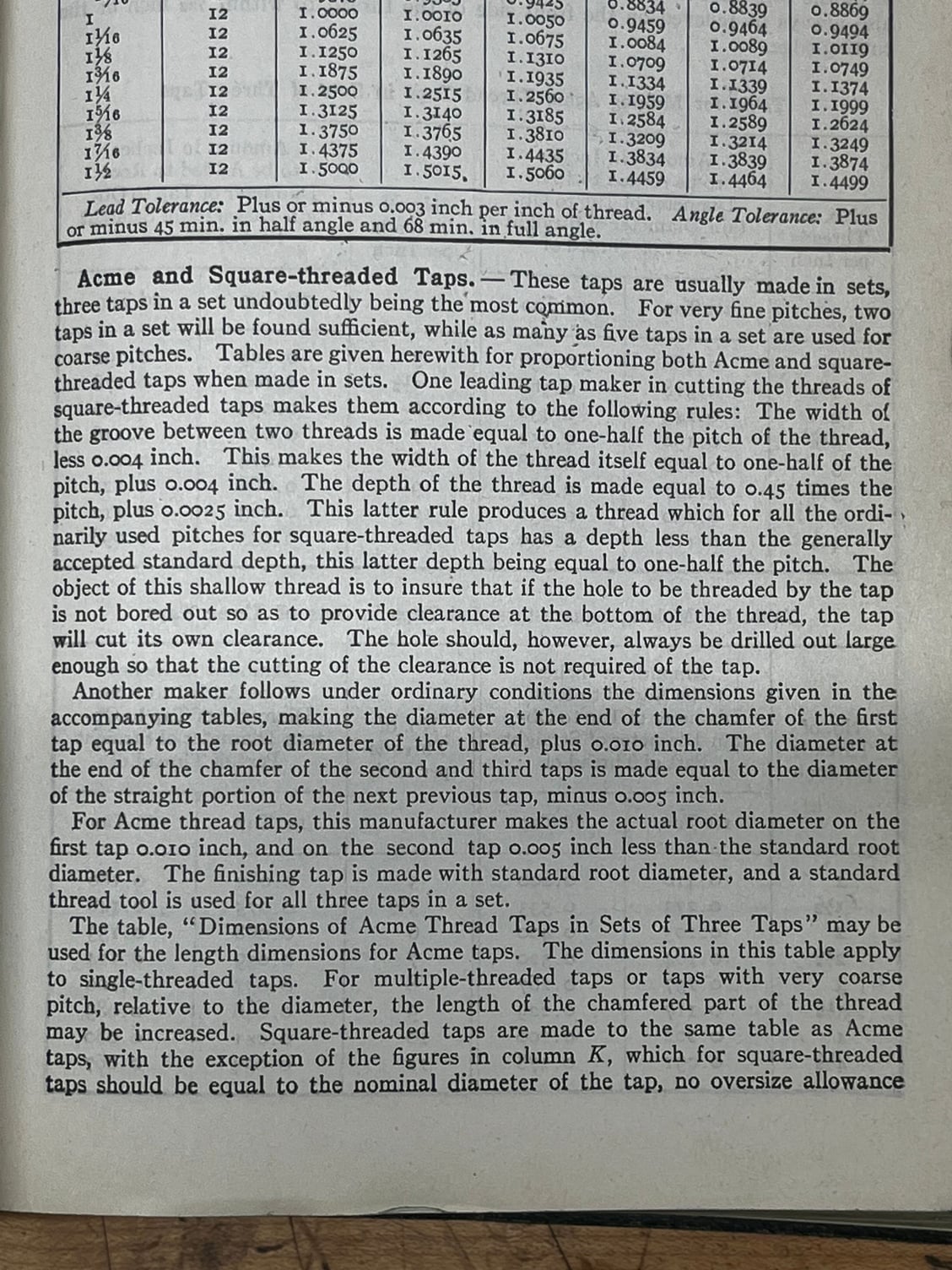

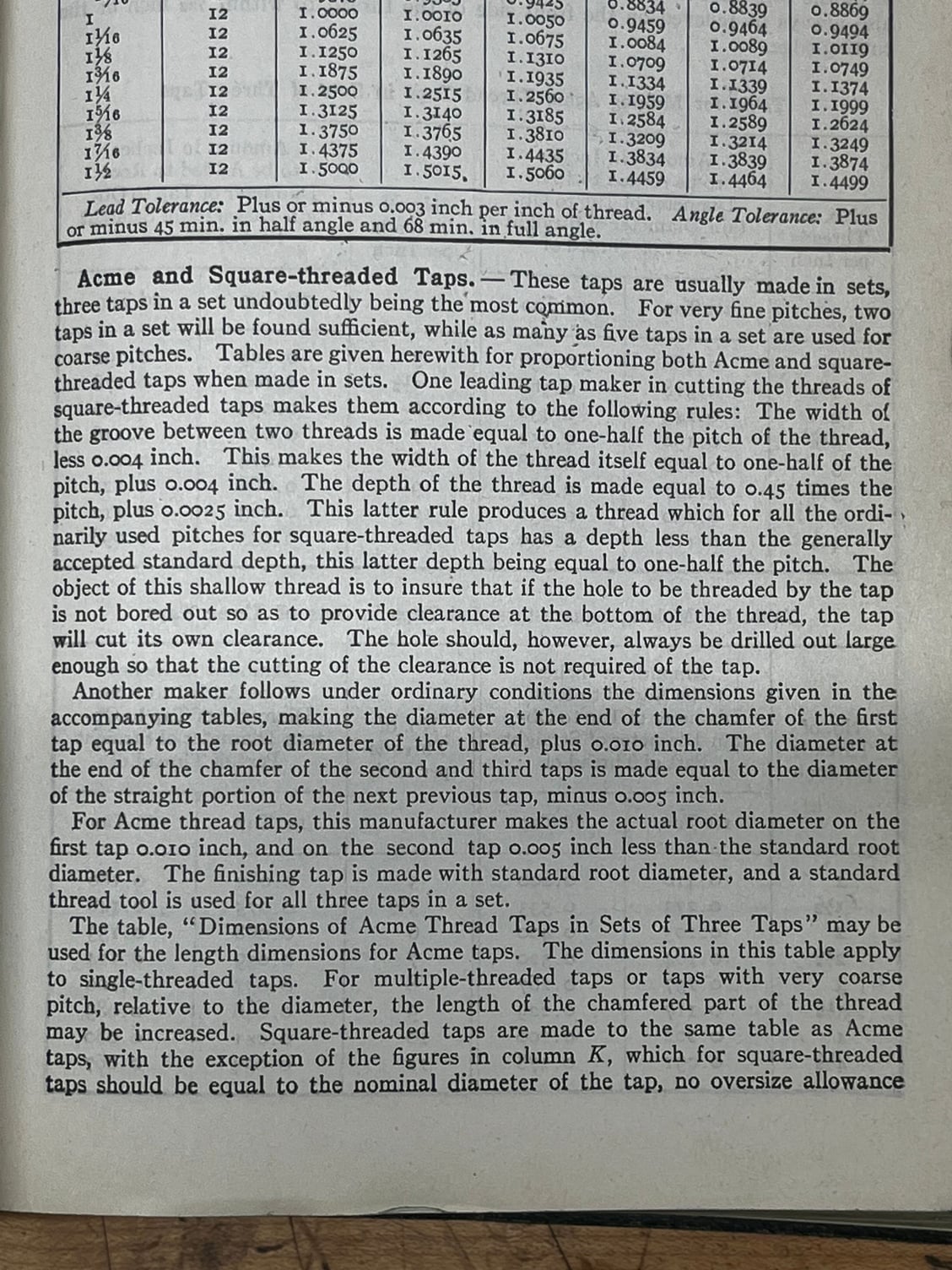

If you looked back a bit, I believe that I mentioned ACME threads, along with a comment that many people use two or three passes with different taps to cut them.

The DIAL MARKINGS on your feed dial will tell you EXACTLY if the screw used is METRIC or INCH. They will also tell you the EXACT pitch.

Pitch is pitch, regardless the thread FORM or type (Single Start Thread).

From the 1954 (11th Edition) Machinery's Handbook. Even the cheapest lathe owner should have a Machinery's Handbook! LOL !

LOL !

Keep em in the bookcase, right next to the (American made) lathe.

The DIAL MARKINGS on your feed dial will tell you EXACTLY if the screw used is METRIC or INCH. They will also tell you the EXACT pitch.

Pitch is pitch, regardless the thread FORM or type (Single Start Thread).

From the 1954 (11th Edition) Machinery's Handbook. Even the cheapest lathe owner should have a Machinery's Handbook!

LOL !

LOL !

Keep em in the bookcase, right next to the (American made) lathe.

Last edited by Jesse Open; 05-15-2023 at 08:27 AM.

My Feedback: (1)

yee-up. "size in decimals for thread count" just^ what I found a few days before I ordered the tap.

drill sizes

G=.2610,

17/64=.2656.

H=.2660,

let's not worry about the half-thousands LOL. I gave the guy the choice. he picked "G" drill. there was another drill at .264. but I can't remember what size was used to refer to it.

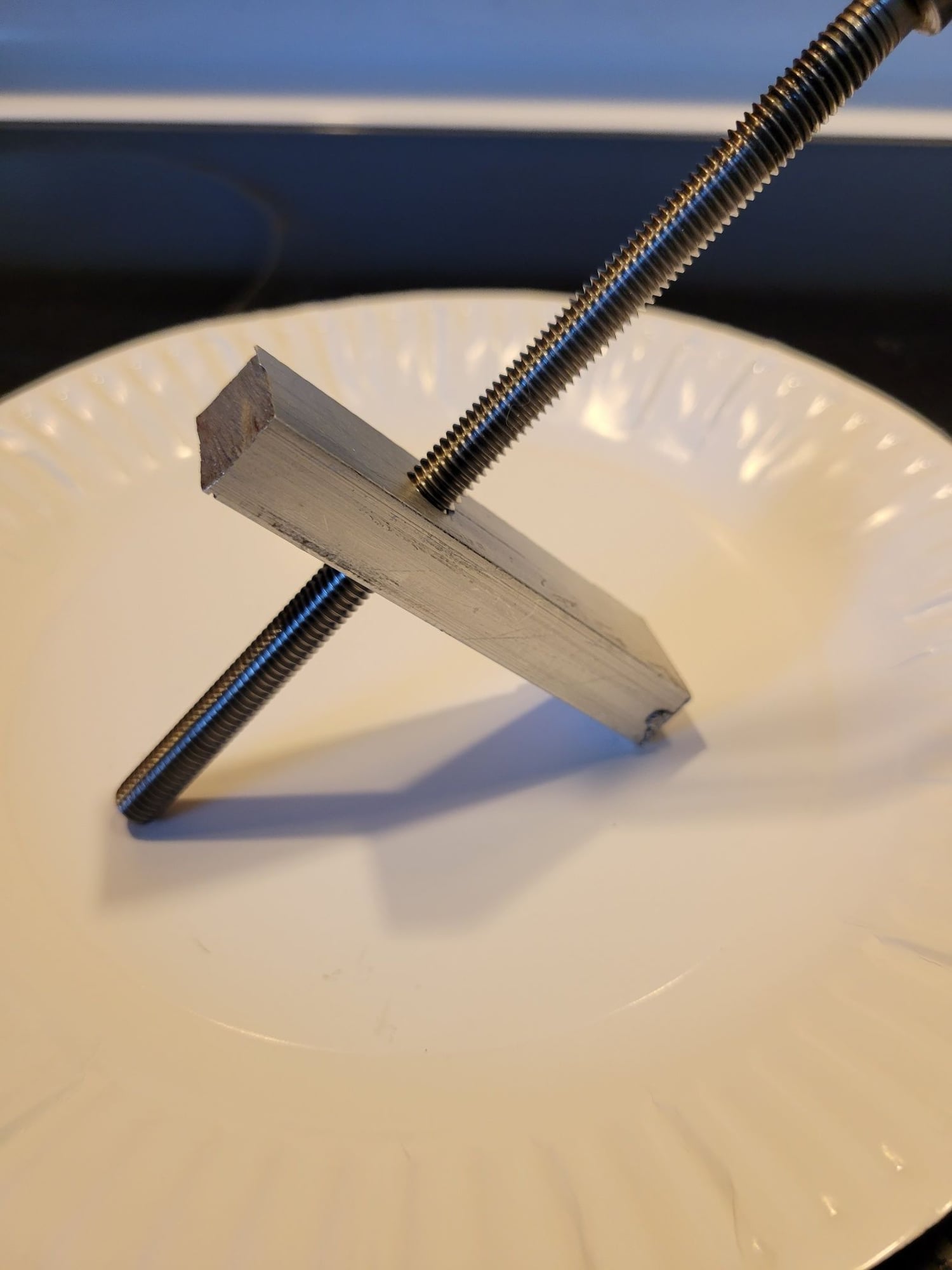

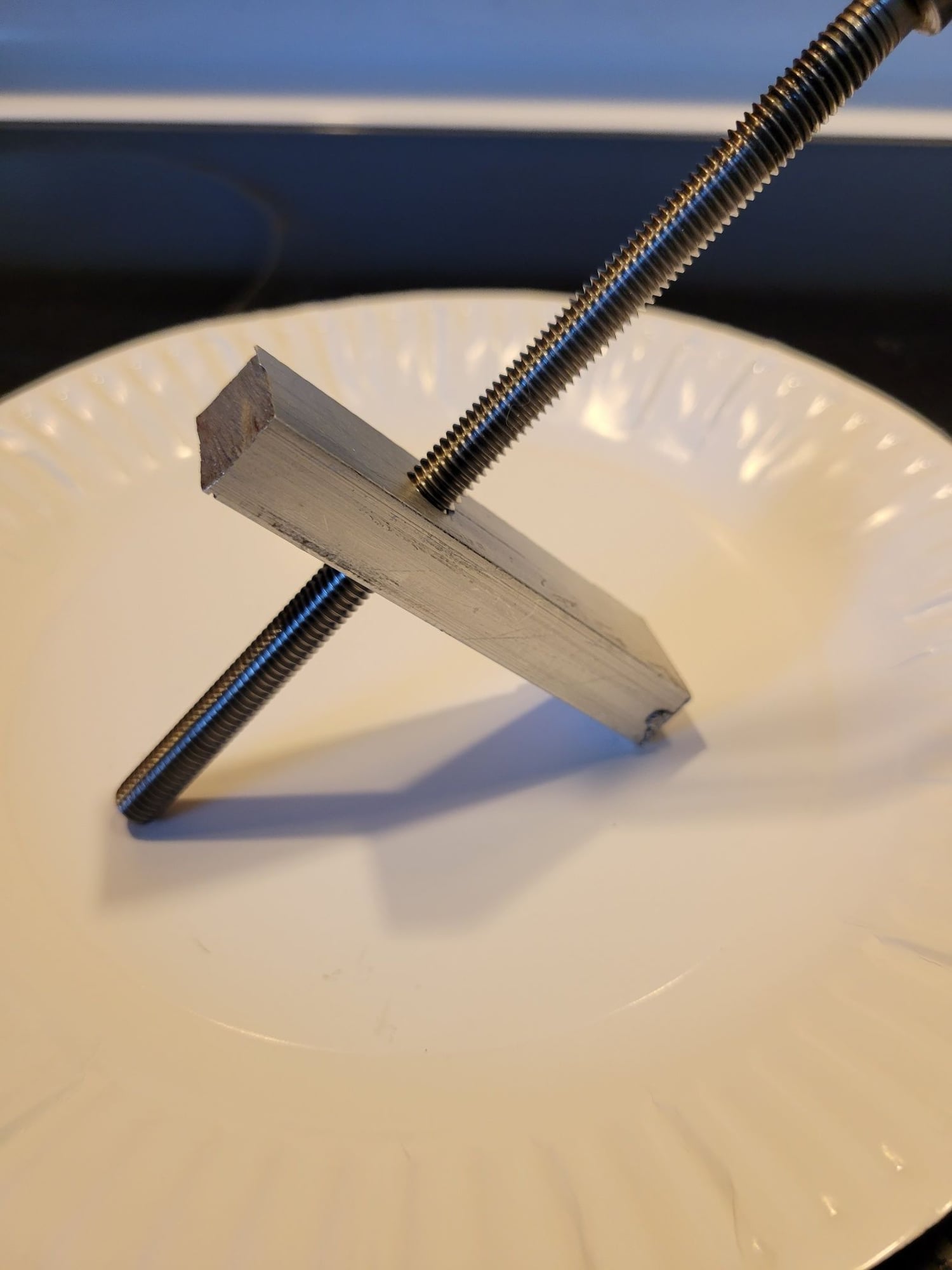

so I received the tap today. held it up to the teeth on my Lead and it fit better than my old thread gauge. I should get the drill today too. I will drill/tap some aluminum before I send the 2 to the guy. hopefully he will buy my $67 Tap for half price LOL. without the use of the correct tools I have a very simple and good method of getting the tap straight on my mill.

oops, edit. and Gary's chart has another decimal size of .2624.

Jim

drill sizes

G=.2610,

17/64=.2656.

H=.2660,

let's not worry about the half-thousands LOL. I gave the guy the choice. he picked "G" drill. there was another drill at .264. but I can't remember what size was used to refer to it.

so I received the tap today. held it up to the teeth on my Lead and it fit better than my old thread gauge. I should get the drill today too. I will drill/tap some aluminum before I send the 2 to the guy. hopefully he will buy my $67 Tap for half price LOL. without the use of the correct tools I have a very simple and good method of getting the tap straight on my mill.

oops, edit. and Gary's chart has another decimal size of .2624.

Jim

Last edited by the Wasp; 05-15-2023 at 12:35 PM.

My Feedback: (1)

The DIAL MARKINGS on your feed dial will tell you EXACTLY if the screw used is METRIC or INCH. They will also tell you the EXACT pitch

Jim

Last edited by the Wasp; 05-15-2023 at 12:57 PM.

Gary, I have had my lathe for some 29 years. mine only tells me decimal, it doesn't tell me pitch, the manual doesn't tell me pitch ether. the new lathes of the same model are the same way. that is why I had so many problems, even the guy that makes the nuts was surprised to find my Lead has standard threads.

Jim

Jim

1"ų 0.050"=20.

As Gary said, don't assume that your tool rest moves inward the same amount as the indicator says, it may move inward half that far because you are cutting a diameter and some lathes are set up that way. Take a reference measurement first, turn the leadscrew one full revolution and remeasure to see how far the tool rest moved.

My Feedback: (1)

It DOES tell you pitch Jim......mathematically. If one complete rotation of your indicator moves your tool rest inward 0.050" then your leadscrew thread pitch is 20.

1"ų 0.050"=20.

As Gary said, don't assume that your tool rest moves inward the same amount as the indicator says, it may move inward half that far because you are cutting a diameter and some lathes are set up that way. Take a reference measurement first, turn the leadscrew one full revolution and remeasure to see how far the tool rest moved.

1"ų 0.050"=20.

As Gary said, don't assume that your tool rest moves inward the same amount as the indicator says, it may move inward half that far because you are cutting a diameter and some lathes are set up that way. Take a reference measurement first, turn the leadscrew one full revolution and remeasure to see how far the tool rest moved.

but the drama continues, I have to laugh cause it's not funny. I received the drill, and,,,,,,, it's shank has a high side, it's not round.

I'm done talking about it, sorry guys.

Jim

One question I do have? I have an Ultra Stik with a 125 mounted and it needs some check up work and see how close to flying it will be. The two 150ís have velocity stacks, but the 125 doesnít? I donít know the original builder, and the family I got it from has no information. I went on the Horizon sight and looked through about 4-450 items. I saw a stack for the 60, but nothing yet for the 125. I remember when the first Saitoís came to our little field, one member said the velocity stacks made for a smoother running engine. Makes sense to this old hot rodder who has studied and run different manifolds. Iíll get some pics together. Iíve been building and flying Rc since 1978 and although I havenít flown in several years due to other pressing issues, Iím eager to get back in the air. Thank you for adding me, bill

Senior Member

I made these my self, the 50 sized one they sell for everything is a little small for the 125. I made these myself, if you have an extra choke clip I'd gladly make one for you 125.

Mr. sportster, that is a very kind and generous offer! Thank you! I now have to locate a choke clip? I have 30 years of some one elseís Rc Gear Iím still sorting through, so it might be a little while?

thanks again, and Iíll keep you updated, bill

Two 72ís and a 150

thanks again, and Iíll keep you updated, bill

Two 72ís and a 150

Last edited by brickwoodward; 05-17-2023 at 11:10 AM.

My Feedback: (1)

LOL hey guys. my American made Drill from McMasters says Brazil on it LOL. now these threads are tighter than the original nut, smoother too.

time to send the Tap, Drill and Lead Screw to Kalamazoo.

Jim

time to send the Tap, Drill and Lead Screw to Kalamazoo.

Jim

My Feedback: (1)

Brickwoodward, Saito used the same velocity stacks for 50 through 82 sized engines. Even though they will fit 91 through 125 engines they are a no go as they will limit horse power output. Saito picked up again with velocity stacks on the big blocks e.g. 120,150 and 180, as well as the 220 Zeus.

Dave's custom velocity stacks are VERY nice and port matched. You should take him up on his offer.

Even better yet, get him to make you a brass one so you can solder on a brass nipple to recirculate the crankcase vent spooge into the stack. Keeps your plane MUCH cleaner.

Dave's custom velocity stacks are VERY nice and port matched. You should take him up on his offer.

Even better yet, get him to make you a brass one so you can solder on a brass nipple to recirculate the crankcase vent spooge into the stack. Keeps your plane MUCH cleaner.

Last edited by Glowgeek; 05-17-2023 at 02:29 PM.

Brickwoodward, Saito used the same velocity stacks for 50 through 82 sized engines. Even though they will fit 91 through 125 engines they are a no go as they will limit horse power output. Saito picked up again with velocity stacks on the big blocks e.g. 120,150 and 180, as well as the 220 Zeus.

Dave's custom velocity stacks are VERY nice and port matched. You should take him up on his offer.

Even better yet, get him to make you a brass one so you can solder on a brass nipple to recirculate the crankcase vent spooge into the stack. Keeps your plane MUCH cleaner.

Dave's custom velocity stacks are VERY nice and port matched. You should take him up on his offer.

Even better yet, get him to make you a brass one so you can solder on a brass nipple to recirculate the crankcase vent spooge into the stack. Keeps your plane MUCH cleaner.